Category: Power Wheelchair

Posted by 2026-01-05 10:01

hoyer lift not working

Comprehensive Guide to Hoyer Lift Troubleshooting: Professional Diagnosis and Repair Solutions

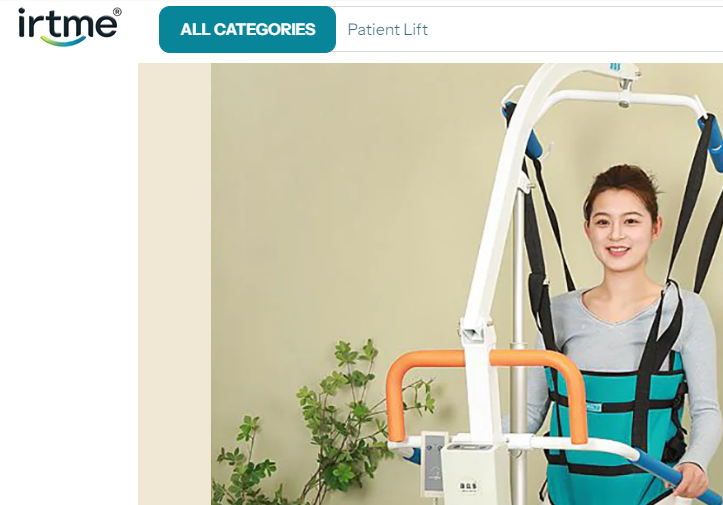

When a Hoyer Lift malfunctions, timely and accurate diagnosis and repair are crucial. hoyer lift not working This article provides complete solutions from basic inspections to professional maintenance, helping you quickly restore the safe operation of the equipment.

Quick Fault Diagnosis Process

Initial Safety Inspection

Stop use immediately: Cease operation right away when abnormalities are detected.

Assess safety risks: Determine if there are immediate hazards.

Relocate the user: Ensure the user is in a safe position.

Record symptom details: Document the fault manifestations and occurrence context in detail.

Systematic Diagnosis Steps

Symptom classification: Identify whether the fault is mechanical, hydraulic, or electrical.

Environment inspection: Check if the operating environment affects equipment performance.

Operation review: Analyze the operation process before the fault occurred.

Historical reference: Review the equipment's maintenance and repair records.

Handling of Common Fault Categories

Hydraulic System Faults

Symptom Manifestations

Difficulty lifting or complete inability to lift

Sudden drop during the lifting process

Hydraulic rod oil leakage

Abnormal looseness of the operating handle

Possible Causes

Insufficient or contaminated hydraulic oil

Worn or damaged seals

Air entering the hydraulic system

Internal failure of the hydraulic pump

Emergency Handling

Check hydraulic oil level and quality

Test the function of the manual pressure relief valve

Perform system air bleeding operation

Contact professional maintenance services

Electrical System Faults (for Electric Models)

Symptom Manifestations

No response at all

Intermittent operation

Abnormal noise or overheating

Battery failure to charge

Diagnosis Steps

Check power connection and battery status

Test the function of control buttons

Inspect fuses and circuit protection

Measure the working current of the motor

Safety Measures

Disconnect the power supply immediately

Avoid disassembling electrical components by yourself

Use the backup manual function

Wait for professional technicians

Mechanical Structure Issues

Common Problem Points

Failure of the leg locking mechanism

Difficulty in boom rotation

Jammed or poorly rotating wheels

Deformed or damaged hooks

On-site Inspection

Check the wear of all moving parts

Test the reliability of mechanical locks

Confirm no deformation or cracks in structural parts

Inspect the firmness of connection points

Step-by-Step Troubleshooting Guide

Step 1: Basic Inspection

Confirm power/battery status

Check hydraulic oil level

Test the function of all safety locks

Inspect wheels and brake system

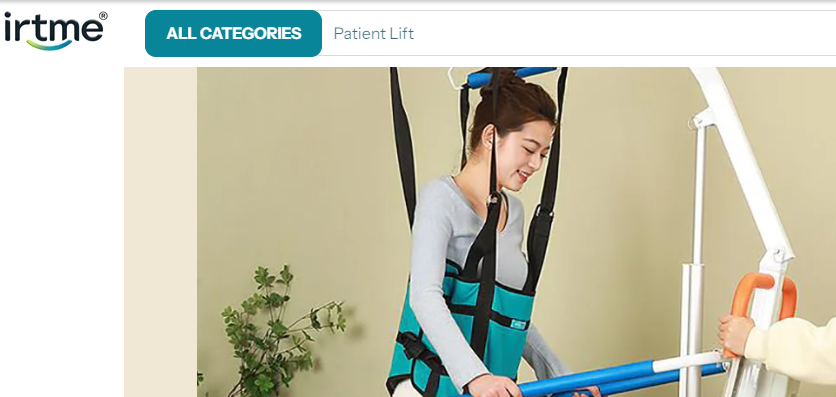

Evaluate the integrity of slings and hooks

Step 2: Function Test

No-load lifting test

Movement test in all directions

Verification of emergency lowering function

Load capacity test (conduct with caution)

Monitoring for abnormal noises

Step 3: Professional Diagnosis

Hydraulic system pressure test

Electrical system parameter measurement

Professional evaluation of structural integrity

Verification of the effectiveness of safety devices

Emergency Handling Plans

Equipment Stops During Lifting

Stay calm and comfort the user

Attempt to operate the emergency lowering device

Seek additional support if the emergency device fails

Contact emergency technical services

Record the entire incident process

Sudden Rapid Drop

Take immediate support measures

Check if the user is injured

Isolate the equipment to prevent reuse

Conduct a thorough safety inspection

Complete the accident report

Abnormal Noise or Vibration

Stop operation immediately

Identify the source of the noise

Inspect relevant components

Perform necessary tightening or adjustments

Test to confirm the problem is resolved

Preventive Maintenance Plan

Daily Maintenance Tasks

After each use:

Clean the equipment surface

Check for visible damage

Test basic functions

Record usage conditions

Weekly inspection:

Conduct a detailed inspection of the hydraulic system

Test all safety devices

Check structural integrity

Clean and lubricate moving parts

Regular Professional Maintenance

Monthly maintenance:

Comprehensive inspection of the hydraulic system

Safety testing of the electrical system

Detailed inspection of structural parts

Performance testing and calibration

Annual overhaul:

Hydraulic oil replacement

Seal replacement

Comprehensive safety testing

Certification and label update

Maintenance Decision Guide

Issues That Can Be Handled by Yourself

Adding hydraulic oil

Basic cleaning and lubrication

Simple adjustments and tightening

Accessory replacement (e.g., slings)

Issues Requiring Professional Services

Hydraulic system maintenance

Electrical system faults

Welding or replacement of structural parts

Maintenance of safety devices

Considerations for Equipment Replacement

Maintenance cost exceeds 50% of the equipment value

Severe damage to major structural parts

Outdated technology with difficulty in obtaining accessories

Safety risks that cannot be completely eliminated

Backup Plan Development

Emergency Alternative Solutions

Manual transfer techniques: Train on safe manual transfer methods

Backup equipment: Maintain backup lifts or transfer devices

External resources: Establish emergency equipment rental channels

Staff deployment: Arrange additional personnel to assist with transfers

Long-Term Backup Plans

Equipment rotation: Establish an equipment rotation system

Preventive replacement: Planned replacement based on service life

Technology update: hoyer lift not working Regularly evaluate new technologies and equipment

Service contract: Sign emergency response contracts with maintenance service providers

Documentation and Record Management

Maintenance Record Requirements

Fault description: Detailed symptoms and occurrence situation

Diagnosis process: Diagnostic methods adopted and results

Maintenance measures: Specific maintenance operations and replaced parts

Test results: Post-maintenance function and safety tests

Recommendations: Suggestions for subsequent use and maintenance

Historical Data Analysis

Track the frequency and type of faults

Analyze the relationship between faults and usage patterns

Evaluate the effectiveness of the maintenance plan

Guide future equipment procurement decisions

Suppliers and Technical Support

Service Provider Selection Criteria

Response time: Response speed for emergency services

Technical capability: Qualifications and experience of professional technicians

Accessory supply: hoyer lift not working Inventory and supply capacity of genuine accessories

Service records: Historical service quality and customer reviews

Service Contract Considerations

Response time commitment: Clear maximum response time

Service scope definition: Included and excluded service content

Fee structure: Clear charging standards and methods

Performance guarantee: Guarantee of service quality and remedies

Conclusion

Hoyer Lift faults not only affect care efficiency but also relate to the safety of users and caregivers. By establishing a systematic fault diagnosis process,hoyer lift not working implementing a strict preventive maintenance plan, and preparing adequate emergency plans, we can minimize the impact of equipment faults. Remember, in medical equipment management, prevention is better than treatment, and regular maintenance is better than emergency repair. Investing in a sound equipment management system and professional technical support is investing in continuous, safe, and high-quality care services.