Category: power lift chairs

Posted by 2026-01-03 11:01

hoyer lift mat

Professional Guide to Hoyer Lift Safety Mats: Essential Equipment for Protection, Stability, and Anti-Slip Performance

During patient transfer processes, Hoyer Lift safety mats play a crucial role. hoyer lift mat This seemingly simple accessory is actually a professional piece of equipment that integrates safety protection, operational convenience, and equipment safeguarding.

Analysis of the Mat’s Core Functions

Safety Protection Functions

Anti-slip Stability: Provides an ideal grip surface for the lift’s wheels.

Impact Absorption: Reduces impact and vibration from the equipment on the floor.

Position Marking: Clearly defines the boundaries of safe operation areas.

Noise Reduction: Significantly lowers noise generated by equipment movement and operation.

Operation Optimization Functions

Smooth Movement: Offers a consistent rolling surface for the wheels.

Floor Protection: Prevents damage to floors caused by heavy equipment.

Hygienic Isolation: Establishes boundaries for clean operation areas.

Visual Guidance: Provides operational guidance through colors and textures.

In-Depth Analysis of Material Types

Rubber Materials

Natural Rubber

Advantages: Excellent anti-slip performance, good shock absorption.

Disadvantages: Heavy weight, may have a rubber odor.

Thickness: Typically 6–10mm.

Service Life: 3–5 years.

Synthetic Rubber

Advantages:

More consistent quality control.

Better chemical resistance.

Lighter weight.

Odor-free.

Disadvantages:

Higher price.

May have lower elasticity.

Vinyl Materials

Medical-Grade PVC

Advantages: Seamless surface, easy to disinfect, liquid impermeable.

Disadvantages: Poor durability, may harden at low temperatures.

Applicable Scenarios: Medical institutions, bathroom environments.

Composite Materials

Multi-Layer Structure

Surface Layer: Anti-slip and wear-resistant layer.

Middle Layer: Shock-absorbing and energy-dissipating layer.

Bottom Layer: Anti-slip fixing layer.

Advantage: Optimal overall performance.

Detailed Explanation of Technical Specifications

Size Standards

Minimum Size: 2m × 2m (covers most operational needs).

Extended Size: 2.5m × 2.5m (for heavy-duty equipment or larger operation spaces).

Customization Option: Customized according to specific space dimensions.

Modular Design: Modular panels for covering irregularly shaped areas.

Thickness Options

Standard Thickness: 6–8mm (balances comfort and stability).

Thickened Model: 10–12mm (better shock absorption).

Ultra-Thin Design: 3–4mm (improves threshold passability).

Tapered Edges: Safety design to prevent tripping.

Surface Textures

Diamond Pattern: All-around anti-slip protection.

Smooth Surface: Facilitates movement of wheelchairs and equipment.

Drainage Hole Design: Specialized for bathroom environments.

Warning Stripes: Visual reminders for boundary areas.

Professional Selection Guide

Based on Usage Environment

Home Environments

Consider aesthetics.

Easy to clean and maintain.

Coordination with home decor.

Storage convenience.

Medical Institutions

Tolerance to medical-grade disinfection.

High durability requirements.

Liquid impermeability.

Compliance with infection control standards.

Bathroom Environments

Absolute anti-slip performance.

Quick-drying capability.

Mildew and antibacterial treatment.

Consideration of drainage design.

Based on Equipment Type

Standard Lifts: Universal mats meet basic needs.

Heavy-Duty Equipment: hoyer lift mat Thickened and reinforced mats are required.

Electric Models: Consider electrical safety features.

Compact Models: Corresponding reduction in mat size.

Installation and Maintenance Specifications

Correct Installation Process

Floor Preparation: Ensure the floor is clean, dry, and level.

Position Confirmation: Identify the optimal coverage area for operations.

Smooth Laying: Eliminate all wrinkles and curled edges.

Fixation Check: Confirm the mat will not shift or slide.

Daily Cleaning and Maintenance

Daily Cleaning: Wipe with a damp cloth and neutral detergent.

Deep Disinfection: Use medical-grade disinfectants; avoid bleach.

Regular Inspection: Check for signs of wear, deformation, or damage.

Storage Requirements: Roll up for storage; avoid folding.

Lifecycle Management

Daily Inspection: Quick visual check before use.

Monthly Evaluation: Detailed inspection of wear conditions.

Annual Testing: Professional performance assessment.

Replacement Standards: Clear safety indicators for replacement.

Key Points for Safe Use

Risk Prevention

Edge Management: Ensure mat edges do not curl up.

Anti-Slip Verification: Regularly test anti-slip performance.

Obstacle Clearance: Ensure no debris is on the mat.

Humidity Monitoring: Promptly wipe up spilled liquids.

Best Practices

Pre-Use Inspection: Incorporate into standard operating procedures.

Regular Rotation: Extend service life.

Proper Storage: Avoid direct sunlight and extreme temperatures.

Staff Training: Include mat usage in training programs.

Solutions for Special Scenarios

Space-Constrained Environments

Custom Sizing: Precisely adapted to available space.

Ultra-Thin Models: Reduce space occupation.

Flexible Modular Combination: Use multiple small mats together.

Quick Storage: Easy to 收起 quickly after use.

Multi-Equipment Areas

Large Mats: Cover the entire operation area.

Color Coding: Use different colored mats for different equipment.

Direction Markings: Provide guidance on operation directions.

Zoned Design: Clearly divide areas for different functions.

Temporary Usage Needs

Portable Design: Lightweight for easy carrying.

Quick Laying: Simple and fast installation.

Universal Sizing: Adaptable to different environments.

Easy Cleaning: Quick disinfection.

Cost-Benefit Analysis

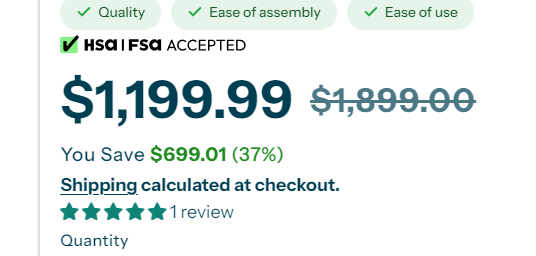

Initial Investment

Basic Models: $100 – $200.

Professional Models: $200 – $400.

Custom Models: $400 – $800.

Installation Costs: Professional installation may be required.

Long-Term Value

Equipment Protection: Extends the service life of the lift.

Floor Protection: Reduces floor repair costs.hoyer lift mat

Safety Benefits: Potential savings from accident prevention.

Efficiency Improvement: Benefits from optimized operation processes.

Trends in Innovative Technology

Smart Mats

Pressure Sensing: Real-time monitoring of weight distribution.

Humidity Detection: Alerts for slippery conditions.

Wear Monitoring: Automatic reminders for replacement.

Usage Statistics: Records frequency and patterns of use.

Eco-Friendly Materials

Recycled Rubber: Manufactured using recycled materials.

Biodegradable Materials: Environmentally friendly alternatives.

Low VOC Emissions: Improves indoor air quality.

Energy-Efficient Production: Reduces energy consumption during manufacturing.

Multi-Functional Integration

Integrated Lighting: Edge-integrated LED lighting.

Heating Function: Heated mats for cold environments.

Antibacterial Technology: Built-in antibacterial agents for continuous protection.

Self-Cleaning Surfaces: Special coatings reduce cleaning needs.

Conclusion

Although Hoyer Lift safety mats are auxiliary equipment, they play an indispensable role in the overall care safety system. hoyer lift mat Choosing the right professional mat not only enhances operational safety but also protects equipment, improves the working environment, and elevates care quality. In the pursuit of optimal care, every detail deserves attention—and safety mats are a key link in this important chain. Investing in high-quality mats is an investment in adding reliable protection to the safe care system.