Category: power lift chairs

Posted by 2026-01-09 13:01

hoyer lift troubleshooting

Hoyer Lift Troubleshooting Guide: Quickly Identify Issues to Ensure Uninterrupted Safe Care

The Hoyer Lift is a critical safeguard for the safe transfer of patients. However, like all mechanical equipment, it may develop malfunctions during use. Whether an electric model suddenly fails to start or a manual one struggles to lift or lower, any malfunction can disrupt care processes and even pose safety hazards. Therefore, mastering basic troubleshooting skills is an essential capability for every caregiver and facility manager.

This guide systematically outlines the symptoms, potential causes, and solutions for common Hoyer Lift issues. It helps you quickly determine the nature of a problem—what can be resolved independently and what requires immediate shutdown and professional repair—thereby minimizing risks to the greatest extent and ensuring the continuity and safety of care.

I. Safety First: When Must the Lift Be Immediately Stopped?

Before attempting any troubleshooting, remember: safety always takes priority over efficiency. If any of the following situations occur, stop using the equipment immediately and attach a "Faulty - Pending Repair" label:

The lift tilts or shakes significantly during lifting/lowering.

The outriggers cannot fully extend or lock securely.

The sling hooks are loose, slip off, or the lifting loops are deformed.

The base, mast, or lift arm has cracks, bends, or broken welds.

Electric models rise or fall automatically without operation.

Manual models slide down slowly after being lifted halfway and cannot maintain height.

Continuing to use equipment with structural or control defects is highly likely to cause patient falls or caregiver injuries.

II. Common Issues and Troubleshooting Steps

1. Electric Hoyer Lift Fails to Start

Potential Causes and Solutions:

Dead Battery: Check if the remote control or main unit has a battery indicator. If there is no display, try charging for 2–4 hours. If it still does not work, the battery may be aging and needs replacement with an original manufacturer’s battery.

Power Not Connected: Ensure the charger plug is securely inserted and the socket has power; hoyer lift troubleshooting some models require pressing the power switch on the unit.

Emergency Stop Button Activated: Check if the red emergency stop button is pressed. If it is, it must be rotated clockwise firmly to reset.

Malfunctioning Remote Control: Replace the CR2032 button battery; try using the backup control panel on the unit. If neither works, the receiver module may be faulty.

Tip: If the equipment has been exposed to water or moisture, do not power it on—send it for repair instead.

2. Manual Hoyer Lift Lacks Lifting Power or Cannot Lift

Potential Causes and Solutions:

Hydraulic Oil Leakage: Check for oil stains around the base. If present, the seal ring is damaged. hoyer lift troubleshooting Do not add regular engine oil yourself—professional personnel must replace the specified hydraulic oil and seals.

Air in the Hydraulic System: This manifests as repeated pumping of the handle with no movement of the lift arm. Try pumping the handle quickly and continuously 20–30 times to bleed air. If ineffective, return the lift to the manufacturer for repair.

Overloading: Confirm the patient’s weight does not exceed the lift’s rated capacity (usually 350–400 lbs). Operating near the weight limit accelerates system wear.

3. Unusual Noises or Jamming During Lifting/Lowering

Potential Causes and Solutions:

Outrigger Joints Lack Lubrication or Are Dirty: Clean the hinges with a soft brush and apply a small amount of silicone-based lubricant (do not use grease or WD-40, as they attract dust).

Deformed Lift Arm Track or Foreign Objects: Visually inspect if the track is straight and remove entangled debris such as hair or threads.

Worn Motor Gears (Electric Models): A continuous "clicking" sound may indicate internal mechanical failure—stop use and send for repair.

4. Excessively Fast or Uncontrolled Lowering

Manual Models: This is usually caused by aging internal seals in the release valve, leading to rapid hydraulic oil backflow. Special tools are required to disassemble this component—do not attempt self-repair; contact an authorized service provider.

Electric Models: This may result from faulty control circuits or solenoid valves. Stop use immediately to prevent patient injuries from sudden rapid lowering.

5. Difficult Wheel Movement or Brake Failure

Check if the wheels are jammed by hair, carpet fibers, or small stones.

Is the brake pedal loose or broken? Some models allow separate replacement of brake components.

If the wheel axle is rusted, lightly apply lubricant (avoid contaminating the floor).

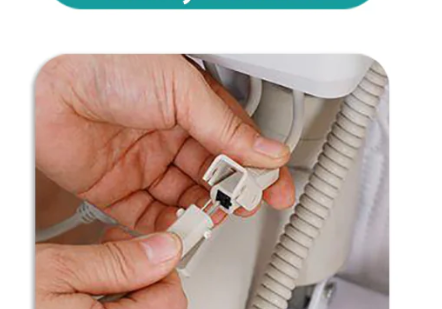

6. Sling Hooks Are Hard to Close or Open Accidentally

Check if the hook springs are rusted or broken.

Confirm the lifting loop size matches the hooks (incompatibility may occur across brands).

If hooks have cracks or deformation, stop use immediately—these are high-risk components.

III. Preventive Maintenance: Avoid Problems Before They Occur

Most malfunctions can be prevented through daily maintenance:

Before Each Use: Visually inspect outrigger locking, sling integrity, and wheel condition.

Weekly: Clean the equipment surface, test the emergency stop button, and check battery level.

Monthly: Tighten visible screws, lubricate outrigger joints, and check hydraulic oil level (manual models).

Every 6 Months: Have professional technicians conduct a comprehensive functional and structural inspection.

Important Reminder: Slings are consumables. Even if they appear intact, hoyer lift troubleshooting it is recommended to replace them every 6–12 months. Sweat, cleaning agents, and UV rays accelerate fiber aging.

IV. Special Recommendations for Home Users

Home caregivers typically lack professional tools, so they should focus on "observation + documentation + seeking help":

Keep the equipment manual and customer service phone number handy, posted near the lift.

Take a photo of the equipment model label for easy remote consultation.

Join brand user groups or follow official WeChat accounts to receive maintenance reminders.

If the equipment has been used for more than 5 years, even if no malfunctions occur, have a professional conduct a comprehensive assessment.

V. When Must You Contact Professional Repair?

Non-professionals are strictly prohibited from handling the following situations:

Repairs involving the internal hydraulic system.

Replacement of circuit boards, motors, or batteries in electric models.

Damage to load-bearing structures (base, mast, lift arm).

Equipment that has been overturned, impacted, or exposed to water.

Repairing through official channels of brands such as Hoyer, Arjo, and Drive Medical not only ensures the use of original parts but also preserves warranty eligibility. Do not choose unauthorized repair shops to save money—a low-quality part can turn the entire lift into a safety hazard.

Conclusion: Malfunctions Are Not the End, but a Safety Warning

Every abnormality in a Hoyer Lift is a signal from the equipment. hoyer lift troubleshooting Responding promptly and handling issues correctly is not only responsible for the equipment but also a respect for the patient’s life.

Genuine professional care does not mean never encountering problems, but knowing how to respond safely when problems arise. Mastering this troubleshooting guide gives you more confidence and less risk.

Because in the world of caregiving, the most reliable safeguard is not a machine that never breaks down—but a caregiver who remains alert, cautious, and responsible when it matters most.