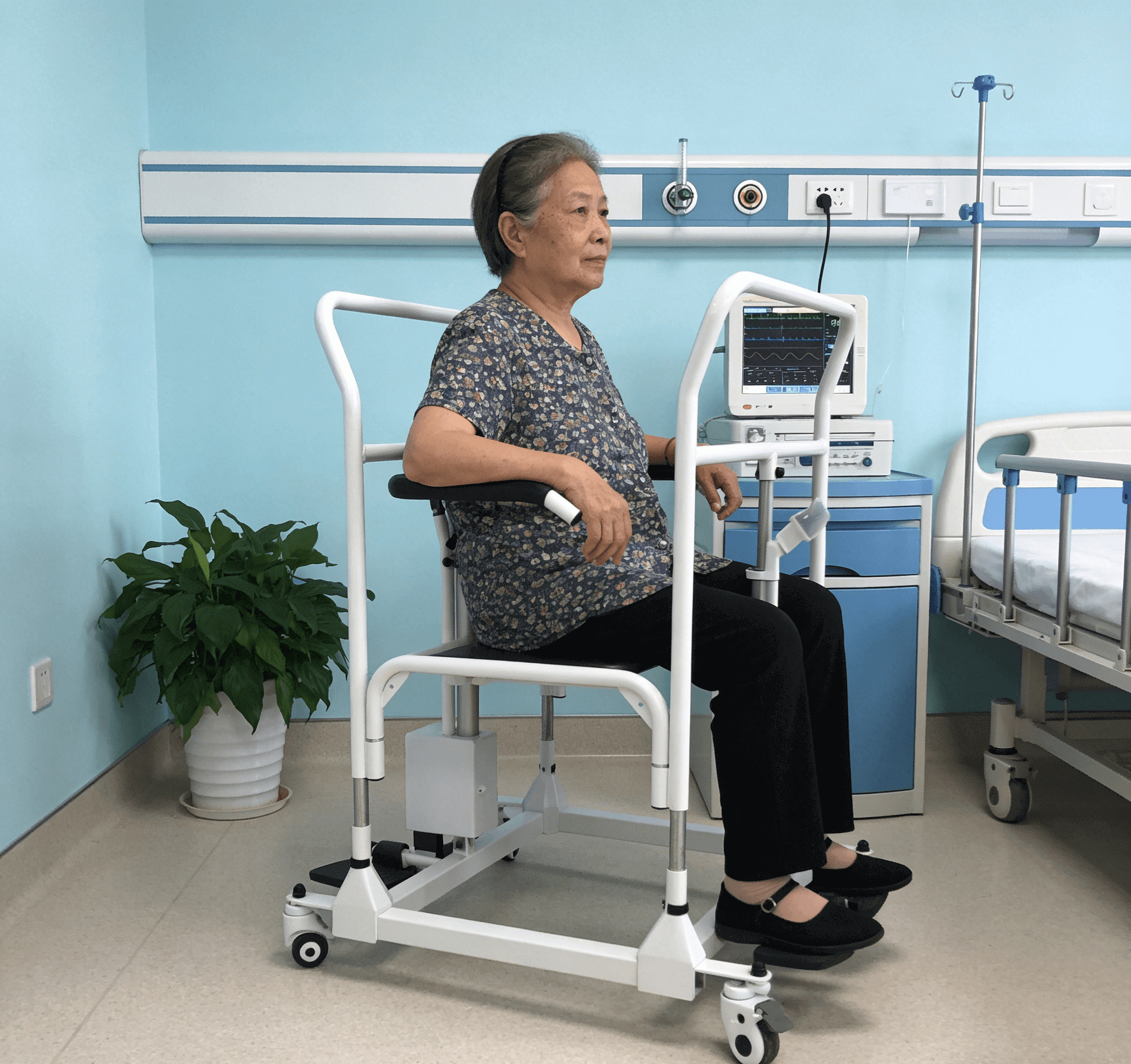

Category: Electric Transfer Chair

Posted by 2025-12-26 11:12

hoyer lift failure

I. What is Hoyer Lift Failure?

"Hoyer lift failure" generally refers to any equipment malfunction or human error that occurs during use, leading to interrupted transfers, loss of control, or safety accidents. This includes but is not limited to:

Sling tearing or slipping off

Sudden dropping caused by hydraulic system pressure loss

Electric motor failure or battery depletion

Base tipping or support legs collapsing

Malfunctioning control buttons or incorrect operation

Boom structure fracture

These failures may result from equipment aging, overloading, lack of maintenance, or operational errors, and often occur as a "superposition of multiple factors."

II. Real Cases: Painful Lessons from Failures

Case 1: Sling Tear Causing Hip Fracture (USA, 2023)

An elderly patient weighing 113 kg was transferred using a standard sling with a maximum capacity of only 100 kg. The sling’s stitching suddenly split during lifting, causing the patient to fall sideways to the ground, resulting in a femoral neck fracture. Postoperative complications led to the patient’s death.

Root Cause: Failure to match the sling’s load capacity to the patient’s weight.

Case 2: Base Tip-Over Due to Unfolded Legs (UK Nursing Home, 2022)

To save time, a caregiver started operating the Hoyer lift without fully unfolding its support legs. During rotation, the equipment’s center of gravity shifted, causing the entire unit to tip over. The patient’s head hit the tiled floor, resulting in a concussion.

Root Cause: Violation of operating procedures + lack of supervision and training.

Case 3: Slow Pressure Loss from Aging Hydraulic Pump (Canada, 2024)

A second-hand Hoyer lift used for over 5 years had not undergone regular maintenance, leading to aging hydraulic seals. During transfer, the patient slowly "settled" mid-air, getting stuck between the wheelchair and the bed, which caused compressive rib injuries.

Root Cause: Neglect of preventive maintenance.

III. Five Main Causes of Hoyer Lift Failure

Cause Category Specific Manifestations Proportion (Based on FDA MAUDE Database Analysis)

1. Overloading Weight or sling exceeding the rated load capacity ≈32%

2. Sling Issues Wear, tearing, mismatched models, incorrect placement ≈28%

3. Operational Errors Unlocked support legs, accidental activation of emergency stop, excessive rotation speed ≈20%

4. Equipment Aging/Lack of Maintenance Hydraulic leaks, motor failures, loose screws ≈15%

5. Environmental Factors Uneven floors, narrow spaces, unstable power supply ≈5%

Note: Most accidents are caused by two or more factors, such as "overloading + sling wear + hasty operation."

IV. Identification of High-Risk Failure Scenarios

Extra caution is required in the following situations:

Using second-hand or unbranded Hoyer lifts (especially products from e-commerce platforms with unknown sources)

Slings with frayed edges, discoloration, unusual odors, or loss of elasticity

Abnormal noises, shaking, or uneven speed during lifting/lowering

Loose control handles or stuck buttons

Operation near slopes, carpets, or door sills

V. Systematic Prevention Strategies

✅ 1. Strictly Match Equipment to User Needs

User’s weight × 1.2 ≤ equipment’s rated load capacity

Select specialized slings (e.g., toileting, bariatric, shower slings)

Ensure compatibility between the sling and the main unit brand (Arjo slings ≠ Invacare main units)

✅ 2. Establish Standard Operating Procedures (SOP)

Pre-use checks every time: locked support legs, intact slings, normal power/hydraulics

Keep the boom vertical during transfer; avoid diagonal pulling

Prohibit single-person operation for high-risk transfers (e.g., obese or agitated patients)

✅ 3. Regular Maintenance and Lifespan Management

Professional inspection of hydraulic/electrical systems every 6 months

Replace slings every 6–12 months (or immediately discontinue use if wear is found)

Evaluate whether to retire equipment after 5 years of use

✅ 4. Strengthen Training and Emergency Drills

All caregivers must pass practical operation assessments

Drill emergency postures for "sudden drops" (e.g., using hands to support the patient’s back)

Post operation flowcharts and emergency contact information near the equipment

✅ 5. Prioritize New Models with Safety Redundancy

Equipped with dual hydraulic circuits or mechanical anti-drop locks

Electric models with low-battery warnings and emergency manual lowering functions

Bases with tilt sensors that automatically alarm when the tilt exceeds limits

VI. Supervision and Reporting Mechanisms

In most countries, Hoyer lifts are classified as Class II medical devices, and adverse events must be reported:

USA: Report via the FDA MAUDE database

EU: Submit through the EUDAMED system

China: Report to the Adverse Event Monitoring Center of the National Medical Products Administration (NMPA)

Timely reporting not only helps trace product defects but also promotes the upgrading of industry safety standards.

Conclusion: No Detail is Too Small for Safety

A Hoyer lift is originally a tool to protect lives, but if it fails, it can also become a source of harm. hoyer lift failure Behind every successful transfer lies respect for the equipment, procedures, and responsibilities. Whether you are a family caregiver or a professional institution, you should remember:

"There are no ‘low-probability’ accidents—only ‘unvalued’ risks."

Investing in compliant equipment, spending ten minutes on pre-use checks, or attending a training session—these small actions may prevent an irreversible tragedy.

Safety Tip: If any equipment abnormality is found, stop using it immediately and contact the supplier or a professional maintenance organization. Never "make do" with faulty equipment.